It’s commonly known that foam surfboards are products of the petrochemical industry. I mean, materials such as EVA, EPA foam and plastic sheets glued together… This synthetic cocktail is hard if not impossible to recycle – and this is exactly why foamies haven’t got the best reputation when it comes to sustainability. Are soft top surfboards just adding to the plastic soup?

We want to introduce some young surf companies that are working on a more eco technology of making soft tops. These brands put it at the center of their surfboard design to minimize environmental impact. New materials and ways of manufacturing have been developed by surfers looking for ultimate fun in the water – without harming the playground that is the sea. These innovative companies are a step ahead of the industry and they’re nicely spread around the globe. Meet Spooked Kooks from Bondi, SkunkWorks from Ireland, Notox Korko from France and Formula Fun and INT from California.

Want to see our infographic on how soft top surfboards are manufactured? See this page.

Spooked Kooks

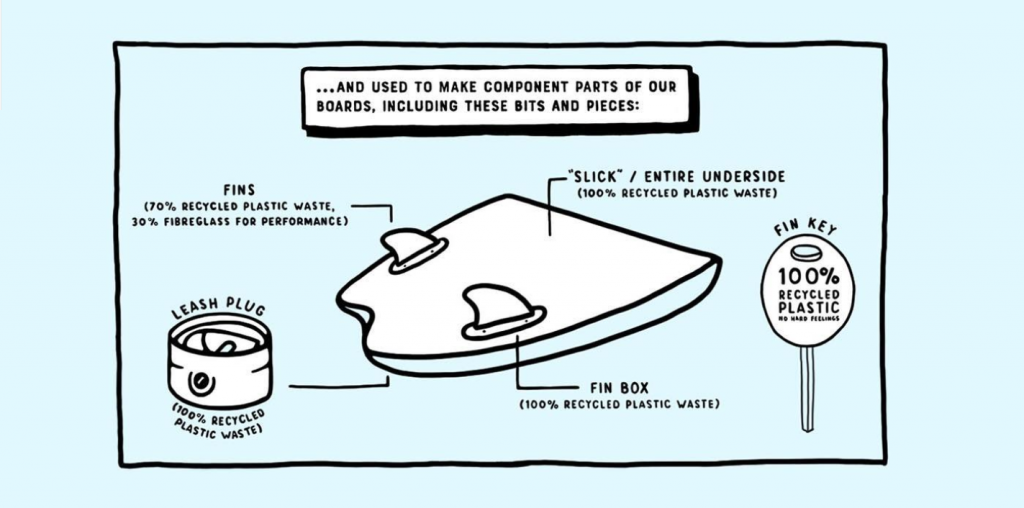

Spooked Kooks’ mission is to make the best performing and most durable softboards containing as much recycled plastic waste as possible. “100% of all high-density polyethylene used in our boards is recycled post-consumer plastic waste. This includes the entire “slick” (underside of the boards), leash plug, fin boxes, fins and fin key.”

The Australian startup is looking at ways to integrate other recycled materials and sustainable non-plastic materials into their foamies. They aim at improving the manufacturing process, as well as packaging, to minimize the amount of new plastic used and waste created.

The company asks it’s buyers to return their soft top back to the factory once it reached the end of life, in return for a 10% discount on the next board. Check them out here.

SkunkWorks

SkunkWorks Surf Co manufactures boards with the purpose to make them last. The founder started a soft top factory in Ireland to make better boards than the ones his brother, a surf school owner, ended up replacing every year. Replacing worn off foamies was the surf schools number one expense. After some years of research, prototyping and testing (and some backing by Richard Branson), SkunkWorks Surf Co was born.

When they started making a name for themselves, the Irish brand focused on a new project: to develop boards with minimal ecological footprint. Their new boards consist of at least 30% recycled polyethylene (that they get from old Land Rovers!). SkunkWorks doesn’t use adhesives: instead of gluing the materials together they use the method of heat bonding. This makes sense, as one of the main reason that soft tops fall apart is the fact that glue doesn’t go well with salty water, sunshine and large temp differences. This makes SkunkWorks boards lose 10 times less chemicals in the water than some competitors’ boards. Instead of rocking funky prints for Insta shots, the Irish foamies put function over form. The cobalt blue boards are pretty much indestructible – which makes them a surf rental favorite.

Interesting fact: instead of wooden stringers, the boards have lightweight aluminum tubes! See more about SkunkWorks on their website.

Formula Fun

This soft top brand has teamed up with the guys from Marko Foam – true surfboard blank specialists. They produce recyclable copolymer blanks for different brands and also for the soft tops of Formula Fun. These foamies are made of a high-density molded copolymer core and molded stringers. Right now, the company offers only the high performance fish model. This board has a corduroy EVA traction pad, which makes surf wax redundant and is set up with a future fins setup. The Californians are proud of their ‘Made in America’ boards and together with Marko Foam and Waves to Waste, are part of an extensive surfboard recycling system in the US. See more about them here.

Notox Korko

Allright, this isn’t your regular soft top. The Korko is a borderline case as it’s not super soft. We haven’t surfed it yet, but some online reviews say that the board doesn’t really surf like a foamie but more like a rigid board – but then wrapped in a thin soft layer. Of cork!

It’s a super durable funboard that handles dings. The French surf board company Notox has developed a board with a cork outer layer – meaning they don’t have to use plastic sheets to make the board feel soft. It looks absolutely unique.

Some basic properties of cork, like it’s buoyancy, it’s grip and impermeability make it a pretty logical natural material for surf boards. The inside of the board consist of an epoxy stringer and a EPS core. To be specific: a recycled EPS foam core that doesn’t absorb water.

Notox is based in the Basque country and that’s where the board for the Euro market are made. What makes this company pretty unique is that they don’t ship overseas. Instead, the Notox team has partnerships with manufacturers worldwide. If you order a Korko in Australia, the board will be made in Australia. With shipping making up a huge part of a surfboards’ environmental footprint – this is a very good move. Check Notox out here.

INT softboards

100% American Made Foam! The California based company INT promises that from design to delivery, every INT board is made at their factory in beach town Carlsbad. For them, soft top production overseas isn’t only an unsustainable way of manufacturing, but also limits innovation and quality control. Louie Hayward from INT says: “Making five bucks more a board by moving to China doesn’t equal out to the back-end advantages of staying here. The risks of having a defected, inconsistent and flawed product just aren’t worth it to me”. (source: Surfer Magazine.)

INT uses 100% recyclable foam blanks and bio-based epoxy resin, which makes this brand of foam boards stand out from the rest. The founders saw a growing demand for both fun and performance boards that would withstand dings and scratches. They wanted to provide an alternative to the factory made one size fits all CostCo boards. That’s why in 2001, they started INT, short for IN Transition. Check them out here.

We’re not there yet, but it’s good to see surf addicts worldwide experimenting with more environmentally friendly surf crafts. Industry insiders say that the big boys such as CostCo (Wavestorm) and Decathlon (Olaian) are also working creating better product life cycles in their CSR strategies. However, they are not too clear about what measures they have actually implemented at this point. The dedicated foam brands in this list get way more eco credits- that’s for sure! And we can’t wait to update this article with more brands committing to more recycling and less waste.